Testing of bearing design

The research work in MarinRes is at present emphasizing the development of prediction models for Rolling Contact Fatigue (RCF) in large bearings and advanced models for fatigue life predictions of welded steel joints.

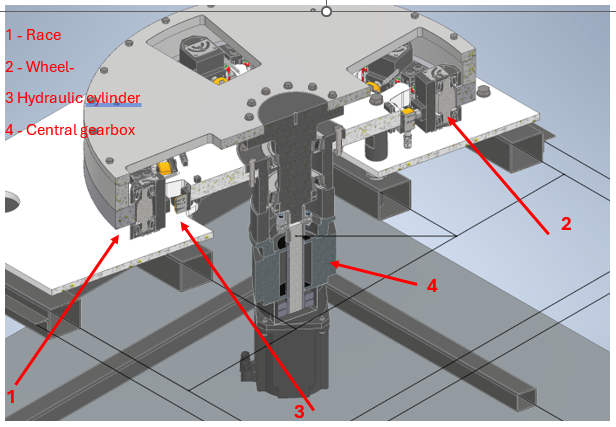

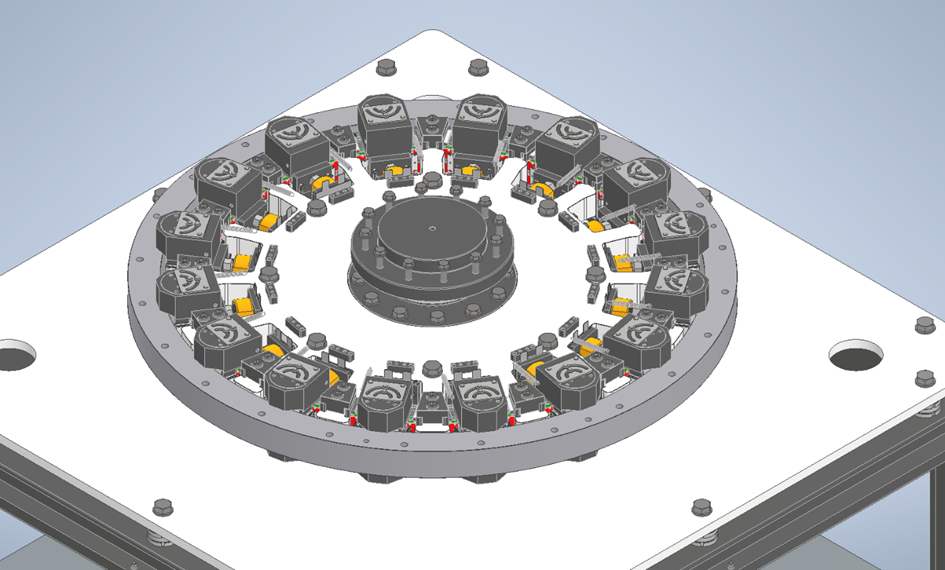

The testing of a scaled main bearing for a turbine generator is starting the first week of January 2026 at the Fraunhofer IWES laboratory in Hamburg. The bearing design concept is developed by Optigen in Barcelona. MarinRes has developed a new prediction model for Rolling Contact Fatigue (RCF). The objective of the testing is to support the material selections made, and to verify the new methodology for the prediction of RCF damage. Creadis has designed the test set-up shown on the picture below.

By courtesy of Creadis

PROMISE: An engineering expert system

It all begins with an idea.

We are developing algorithms to facilitate the analysis and prediction of the potential damage processes discussed in section 3. The expert system is designated Probabilistic Models in Structural Engineering (PROMISE)

PROMISE is a software package that gives support for predictive-based decisions in design, maintenance and inspection planning of load bearing structure and machine elements. The package is developed in modules for important topics within these fields. The objective is to give the analysts and practicing engineers a toolbox based on the state-of-the-art for design against time-dependent damage mechanisms. Some of the modules are introducing innovative steps in the probabilistic modelling that are beyond the-state-of-the-art. The objective is to conceive a robust optimized design with high reliability against potential time-dependent damage mechanisms and associated failure modes.

The software package shall be an aid for conducting predictive-based decisions in design, maintenance and inspection planning of load bearing structure and machine elements. Experience gained from the design and maintenance of offshore oil and gas installations is used as basis. In-service experience and collected experimental data and systemized as basis for the established models. The models are adjusted and fitted to experimental statistics for the various actual damage mechanisms. The work is ongoing and is presented as a modular software package for given structural items and specifics damage mechanisms. Some of these modules were originally developed in Excel spreadsheets and/or by applying MATLAB. Further development will be carried out by using the free-of-charge R software supplemented by Python algorithms. The expert system is developed as separate modules.

Module 1 General descriptive statistics, with emphasis on the simple probability models that are often applied in mechanical and civil engineering. Details on the Lognormal and Weibull distributions. Applications for reliability and failure rate functions. Linear regression. The principles of Monte Carlo simulations and Markov Chain models.

Module 2 Logical tools and diagrams for Hazard Identifications (HAZID), Hazard and Risk Assessment (HIRA), Failure Mode Effect and Criticality Analysis (FMECA), and Hazard and Operability study (HAZOP)

Module 3 Reliability Centered Maintenance (RCM) and Risk-Based Inspection (RBI) planning.

Based on classical methodology, the models are established for predictive maintenance and condition monitoring. The general trend is that scheduled maintenance is replaced by predictive maintenance based on the implementation of efficient monitoring systems. The RBI for fatigue damage is based on engineering fracture mechanics model as suggested by DNV, but the Markov Chain Model is preferred as a first approach. Furthermore, Monte Carlo simulation Is preferred instead of the FORM/SORM. These preferences are chosen because the approaches are less abstract and easier to understand and apply. Consequently, the chosen models will be easier to handle for the practicing engineer without any loss of precision in the obtained reliability predictions and risk analyses. In the development of these probabilistic models, it is important that the understanding of underlying physical model for the given damage mechanisms is not lost. It is of vital importance to have detailed knowledge of the actual damage mechanisms that a chosen condition monitoring system is expected to reveal.

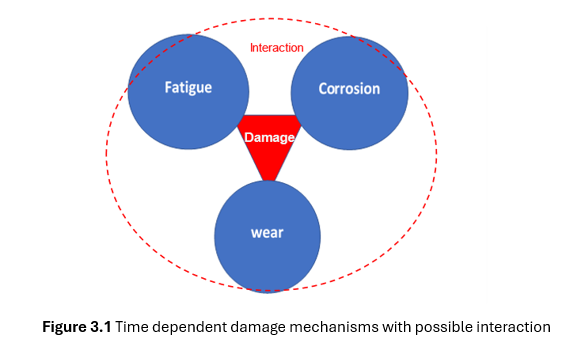

Module 4 Probabilistic models for time-dependent damage processes in load bearing structures

The module emphasizes reliability-based life predictions for fatigue, corrosion, and wear damage. The fatigue and wear models account for possible multi-axial stress states by adopting the Dang Van fatigue criterion. Hence, the uniaxial normal stress component is not considered as the only important variable for the damage process. This uniaxial limitation is often found in the current international building codes and national standards. Furthermore, the interaction between fatigue and wear is fully recognized. Furthermore, the conventional linear relation between the stress range and the number cycles to failure for log-log scale is replaced by a non-liner model by using the Random Fatigue Limit Models (RFLM). These are innovative steps that are beyond the state of the art. The obtained models give better precision in the reliability predictions than obtained by common models as presented in existing rules and regulations.

Module 5 Special tailored applications for critical structure items and machine elements

Applications from module 4 are adapted for:

· Welded structural details subjected to fatigue loading in service

· Mooring system with focus on chain segments and steel ropes

· Machine elements such as bearings and tooth wheel

Most of these items are found in offshore oil and gas installations, in ship structures, and in offshore wind turbine installations. The latter type of installation is developing vigorously at present and the Life Cycle Cost (LCC) for these installations must be minimized to make them competitive in the energy market. This minimization depends on predictive-based decisions in design, maintenance, and inspection planning.

Module 6 A specialization for girth welded steel risers

The model for welded details in module 5 is elaborated and adjusted against Variable Amplitude Loading (VAL) life data obtained from resonance testing carried out in the laboratory. The RFLM gives better precision in describing the test data than the conventional S-N curves do. The results are promising in the way that the life predictions at a given probability level of survival are more optimistic for long lives.