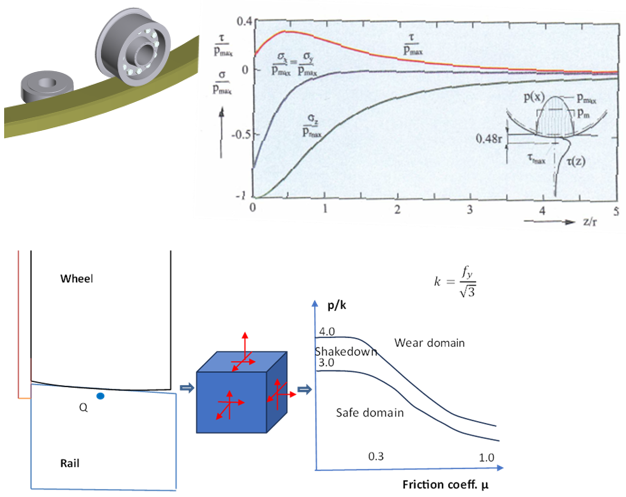

Rolling Contact Fatigue in turret bearings

To allow ship-shaped FPSO to weathervane, large turret bearings are often installed in the forward part of the installation. A design study was conducted by Marinres at a request from BW Offshore, Arendal. A bearing concept based on wheel and rails was proposed. New innovative models for Rolling Contact Fatigue (RCF) life predictions were developed.

Strength and durability of steel reinforced rubber hose

Bonded offloading hoses made of steel reinforced rubber are often important items in offshore mooring systems for crude oil offloading. The hose qualification according to current international requirements is primarily based on testing for important loading modes, particularly internal pressure, tension, and a combination of tension and bending. With this experimental approach, high safety margins are required between the tested strength capacity and the forces acting on the hoses during operation. Furthermore, life predictions for time-dependent damage mechanisms need not always be carried out when applying these guidelines. Hence, life predictions for potential time-dependent damage mechanisms are often omitted. However, it has in the recent years become a requirement from the operators to specify a safe life limit for the purchased hoses. Typical damage mechanisms that may develop during service life are related to corrosion of steel end fittings, fatigue of rubber and teel details and aging of rubber. On this background, Marinres has contributed to establish reliable prediction models for these damage processes to prevent the associated failure modes. A design methodology based on the guidelines given in API 17K specification for Bonded Flexible Pipes has been developed.

In conclusion the project has made contribution to:

· A more reliable design of new loading hoses including detailed life predictions

· The project has generated models and data that can be used for life extension of hoses inn service

The design methodology may also be made applicable for loading hoses planned to be used for transferring CO2 underneath the seabed for permanent storage. There are at present several projects aimed at such an application.

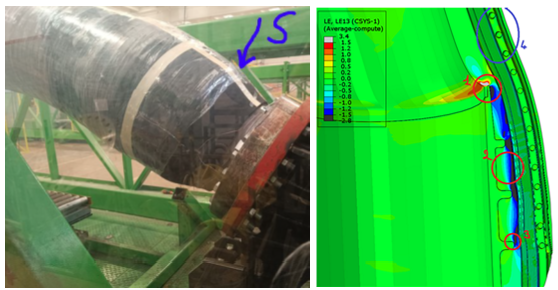

Top picture: Test frame for extreme load and fatigue testing of full-scale hoses in the laboratory at Ortona, Italy. (Courtesy Alfagomma, Ortona, Italy)

Bottom picture: Shear strain at the rubber close to the nipple end under combined tension and bending. (Courtesy Alfagomma, Ortona, Italy).

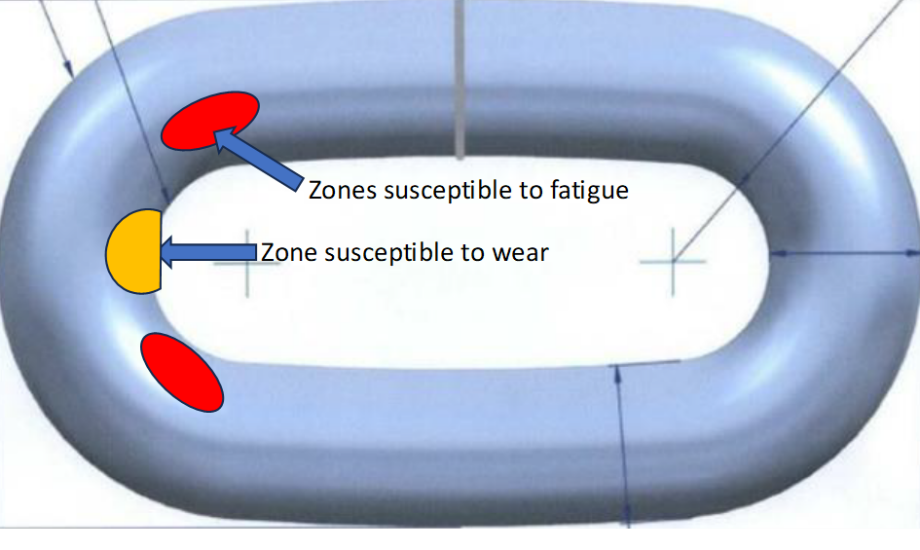

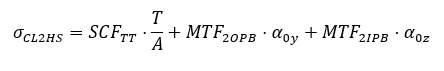

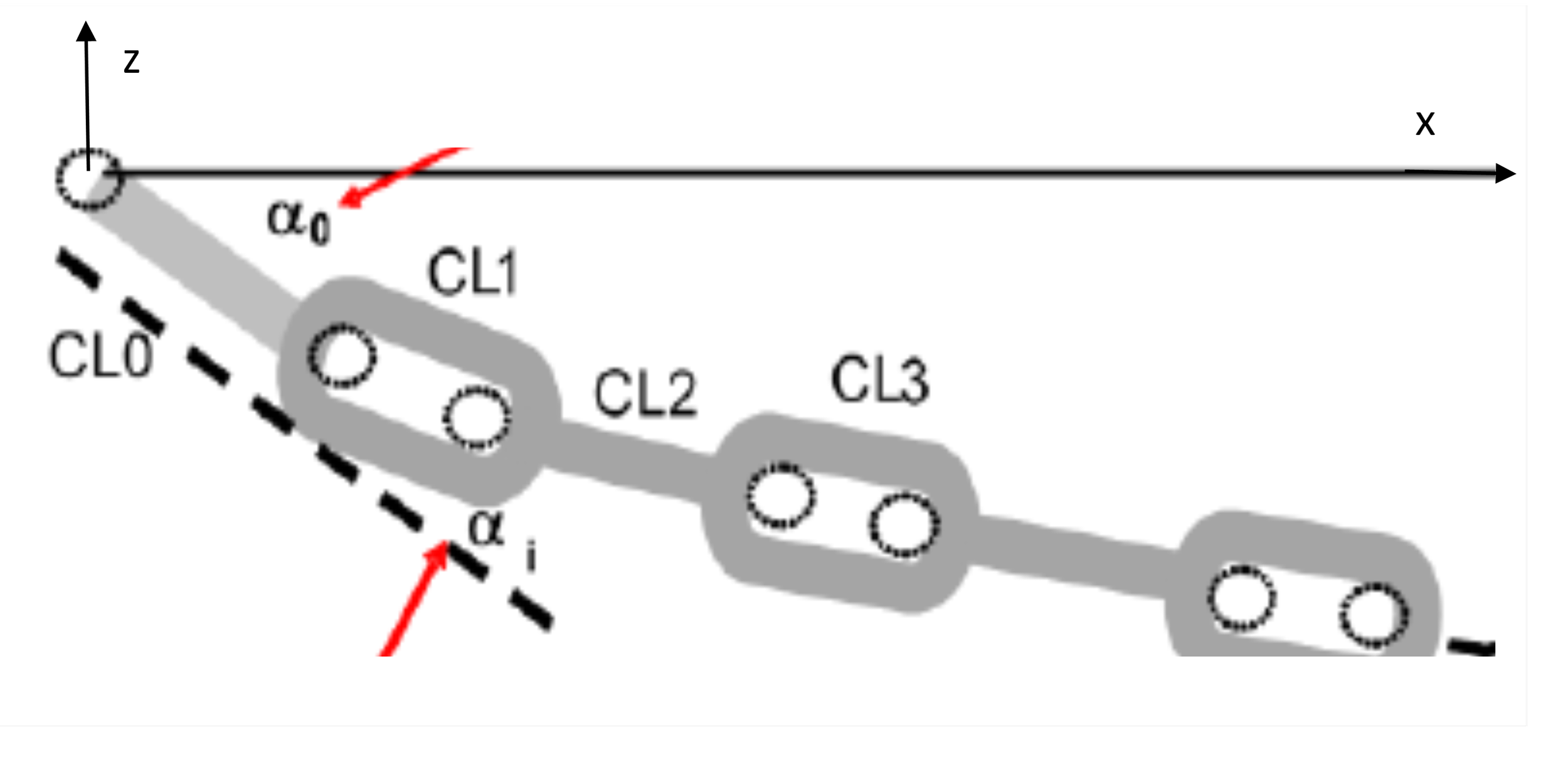

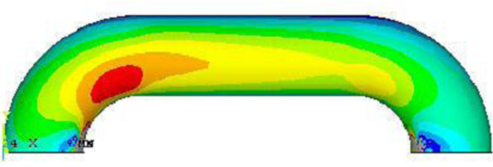

Fatigue and wear of mooring chain for offshore floaters

A feasibility study was carried out in 2022 for a Sevan FPSO at the Wisting field in the Barents Sea. The focus was on wear and fatigue life predictions of the mooring chains.

Load analyses and stress plots were produced as a foundation for operational life calculations. When a link is subjected to Out-Of-Plane Bending (OPB), the hot spots move out of the mid-plane.

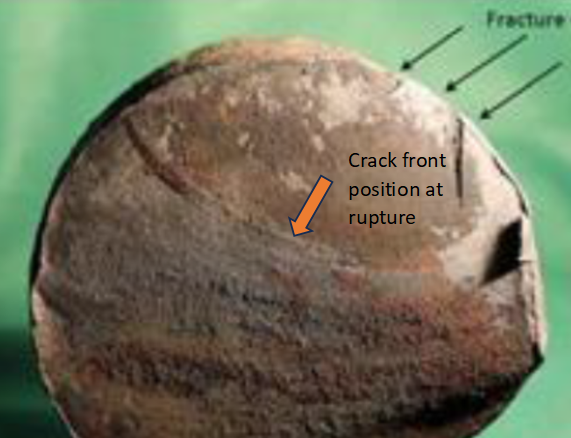

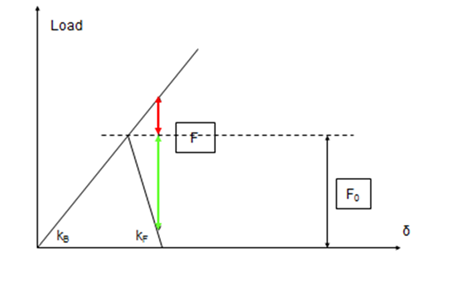

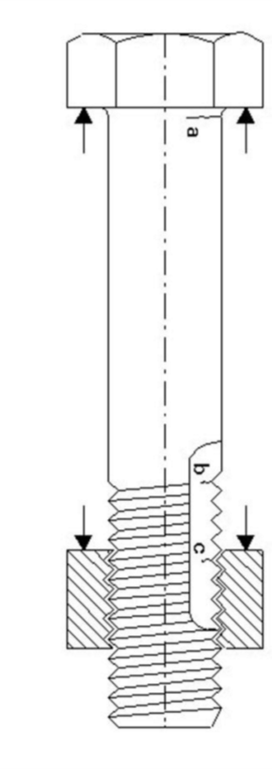

Brittle fracture of high strength bolts

Assessments were made regarding the risk related to hydrogen induced cracking and fatigue in high strength bolts used in connections with cathodic protection in marine environment. Laboratory tests were carried out as basis for the assessments. Professor Hugh Middleton made a major contribution to this project.

Pictures: Upper left-hand: slow strain testing of high strength steel bolt, Upper right-hand: potential crack locations in bolt. Lower part: load transfer in bolted connections.